Challenge 1:

Context based logistics flows

You need to be able to apply different logistics flows based on various contexts: different carriers, inconsistent stock availability, various packagings, different time of reception etc. With Moove, you will be able to redirect operations to another logistics flow, add new steps on the fly inside a flow (i.e. to handle handover places, and to apply rules on specific domains only).

Added value offered by Moove:

- Adaptability:

configure the most efficient flow for each context - Awareness:

apply the logistics flow at the time you'll process the operations - Precision:

tackle particular cases with a wide range of setup possibilities

Challenge 2:

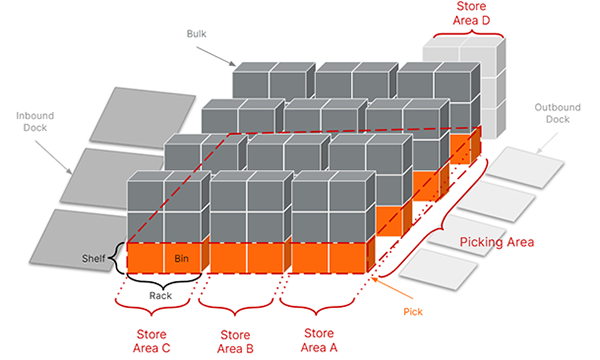

Physical constraints & put aways

You want to respect physical constraints like height, weight etc. and warehouse topology and to always put away products in the ideal location, applying advanced strategies by zone like chaotic, chaotic ABC, same lot etc.

Added value offered by Moove:

- Efficiency:

distribute your products across locations according to their rotations class - Agility:

change your placement strategy as your business evolves - Reliability:

respect physical constraints

Challenge 3:

Streamlined flows using package ID

If you need to manage logistics units with a unique ID related to its context (order, customer, planned destination etc.) and its attributes (type of storage, quantity, product, etc.), Moove will provide you with the necessary functionalities, making it possible to label each logistics unit during the inbound process. Further, it will allow you to process just-in-time transactions by logistics unit and not documents.

Added value offered by Moove:

Speed:

free the next operation at logistics unit level and lower the number of scans to complete an operationReliability:

reduce errors in the processing of the operationsAwareness:

always relate any package in the warehouse to its context

Challenge 4:

Parallel operations

If you need to release parallel batches of operations based on current workload and context and to operate in an efficient sequence to respect service level agreements, Moove lets you manage priorities and split logistics flows in proper operation types using rules.

Added value offered by Moove:

Throughput:

parallelise operations and coordinate many operatorsEfficiency:

drive the sequence of operations and related prioritiesPrecision:

tackle particular cases with a wide range of setup possibilities

Challenge 5:

Low material handling

For questions of efficiency, you might want to pick goods on the shortest paths, without changing product packaging whenever possible.. Moove lets you define reservation rules by zone and product and manage storage and pickable locations, relying on standardized product packaging information.

Added value offered by Moove:

Efficiency:

move goods in original packaging whenever possibleReliability:

reduce mistakes by standardizing the packaging definitionsPrecision:

manage pickable and storage location, organize priorities among them

Challenge 6:

Efficient guiding and monitoring

If you need to guide operators through hand-held devices according to priorities, Moove includes a robust and configurable barcode app that provides the best scanning sequence for each job and allows you to configure your action and menu items 100% web based. Targeting 0% errors on customer order deliveries, Moove also contains a dashboard to receive alerts and monitor capacities, in order to help you quickly identify and solve bottlenecks and edge cases like inventory loss, changing lots etc.

Added value offered by Moove:

Efficiency:

constantly drive your priorities based on the current contextQuality:

educe mistakes using the configurable barcode appPrecision:

handle edge cases with clean embedded processes

Project Stakeholders

Rock your Logistics with advanced operations

During this presentation given on the occasion of Odoo Experience 2020, Joël Grand-Guillaume, Head of Business Department at Camptocamp, gave an overview of advanced features to handle complex warehouses setup using the Open Source OCA Moove Suite.

Using a real case scenario, he went through a complete incoming-stock-outgoing process together and highlighted how those features apply in real life:

- Multi storage type, storage strategies and constraints

- Stock allocation rules, internal operation split by zones

- Guide operators through multi-stage material flows and hand-held devices

- Automate replenishment via a self-learning DDMRP driven set-up

- Interconnection of automatic & manual storage systems

Are you interested in Odoo Moove?

Career

Interested in working in an inspiring environment and joining our motivated and multicultural teams?